Building information modelling (BIM) in healthcare projects can help managers overcome traditional challenges with communication and collaboration. Contractors, architects, modellers, owners, fabricators, and designers all have to work together to ensure the successful completion of building projects. BIM maximizes value and reduces waste between these positions during construction for healthcare projects. Whether it’s creating a new hospital division to handle more patients or a complex MEP system for a bio-technology lab, BIM models can simplify construction, design and approval operations. More than 60 percent of hospital construction companies that have used BIM have finished their projects ahead of schedule and under budget, according to PBC Today.

Clark Construction, along with architects HKS and Shalom Baranes, used BIM models to assist with a project in Washington, D.C., according to Construction Dive. The construction project is scheduled to be completed in 2023. It is for a new healthcare facility for MedStar Georgetown University Hospital. The 477,213-square-foot medical and surgical building will incorporate 156 patient rooms, 32 exam rooms and a rooftop helipad that has immediate access to 31 operating rooms. The ongoing construction project also includes a 600-car, below-grade parking garage, 18 elevators and 6 acres of additional green space.

The construction site is on the land of a former building that was shut down in 2010 after mold had been found in the psychiatry department. This created issues for the project team. It had to relocate miles of water utility lines outside of the building footprint before the project could begin. It then designed and engineered a 250-foot-long utility bridge to support chilled water and electrical services from the central utility plant to the existing MedStar Georgetown Hospital.

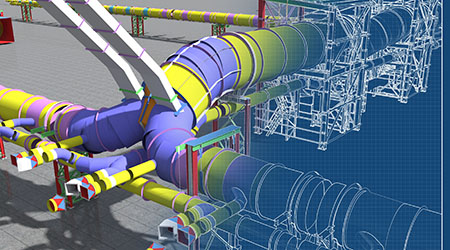

Using BIM, the project crew worked closely together to put together a model of the existing utilities. As design and engineering processes progressed, the BIM excavation model was developed. BIM software allowed the crew to better inform the cost model with respect to deep foundations and begin revising the excavation plan.

BIM helped the construction crew in Washington, D.C., to understand the site and its development at a deeper level. It allowed for the constant revision and resequencing of excavation plans in advance of the field crews. Clark construction and the architects were able to have a comprehensive profile of the expected plan well in advance of the final phase of excavation.

What 'Light' Daily Cleaning of Patient Rooms Misses

What 'Light' Daily Cleaning of Patient Rooms Misses Sprinkler Compliance: Navigating Code Mandates, Renovation Triggers and Patient Safety

Sprinkler Compliance: Navigating Code Mandates, Renovation Triggers and Patient Safety MUSC Board of Trustees Approves $1.1B South Carolina Cancer Hospital

MUSC Board of Trustees Approves $1.1B South Carolina Cancer Hospital Study Outlines Hand Hygiene Guidelines for EVS Staff

Study Outlines Hand Hygiene Guidelines for EVS Staff McCarthy Completes $65M Sharp Rees-Stealy Kearny Mesa MOB Modernization

McCarthy Completes $65M Sharp Rees-Stealy Kearny Mesa MOB Modernization